Mr. Masahiko Miki (General Manager, left of the photo)

Mr. Taiju Iijima (Manager, right of the pohoto)

Post Sales Department

SCREEN GP Service Japan East Co., Ltd.

Evidence over argument. The C-7000 is an indispensable sales tool to convince customers with figures and graphs.

SCREEN GP Service Japan East working to solve problems in the color evaluation environment for printed materials.

SCREEN GP Service Japan East Co., Ltd. (GPSE) was established in 1977 to provide maintenance services for graphic solutions within the SCREEN Group (a subsidiary of Dainippon Screen Mfg. Co., Ltd. at that time). Currently, GPSE has set up major bases in six locations in the eastern Japan region, and by deploying experienced engineers, provides installation, maintenance, and operation training for SCREEN products in the printing industry, as well as solution businesses such as workflows, networks, and color management. As a member of the Japanese Society of Printing Science and Technology, GPSE is also actively involved in the formulation and dissemination of industry standards, in addition to sales and maintenance of its group's products.

Straight tube LED lighting “Tino4000RA98P” for color evaluation of printed matter

The appearance of printed materials such as product packaging, advertisements, magazines, catalogs, and posters forms the image of the product, and is the basis for consumers when selecting and purchasing products. Furthermore, specific colors and color schemes, for example corporate colors and brand colors, convey the corporate image and the world view of the brand, helping to improve corporate and brand values.

Since the colors of printed materials are linked to the value of products and brands, as well as corporate value, it is extremely important to check whether the intended colors are being printed correctly. Therefore, it is necessary to prepare an appropriate lighting environment at the site where color evaluation of printed matter is performed, that is the printing site, proofreading room, design room, and client conference room. Major challenges are to realize a lighting environment that can reproduce natural colors and achieving the same level of environment at different sites.

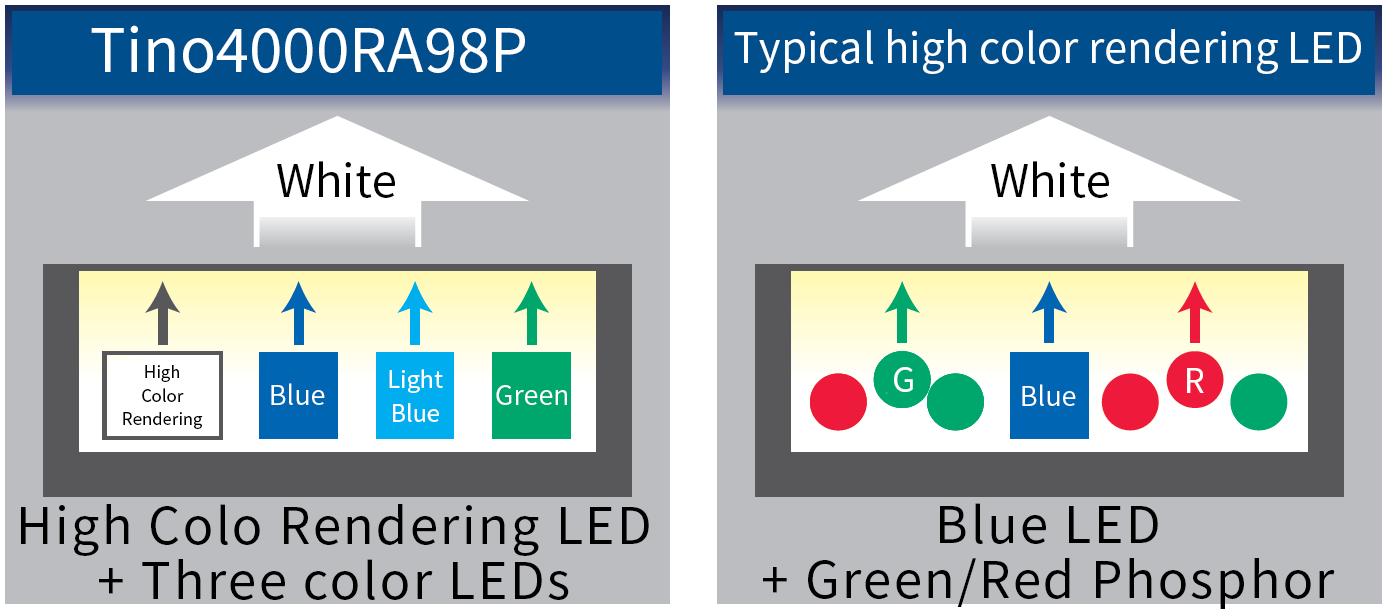

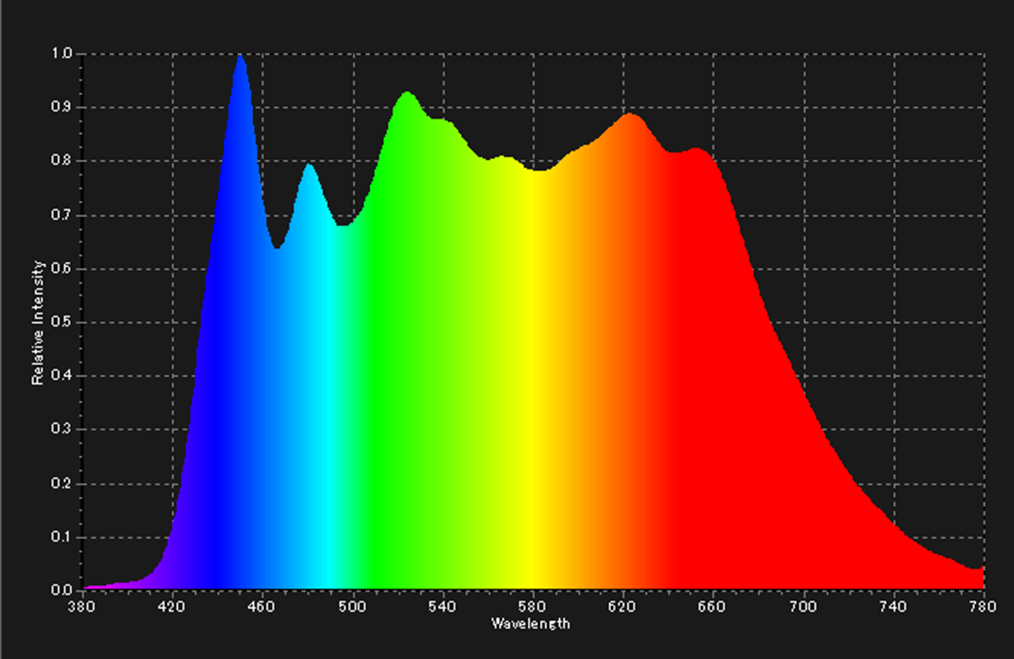

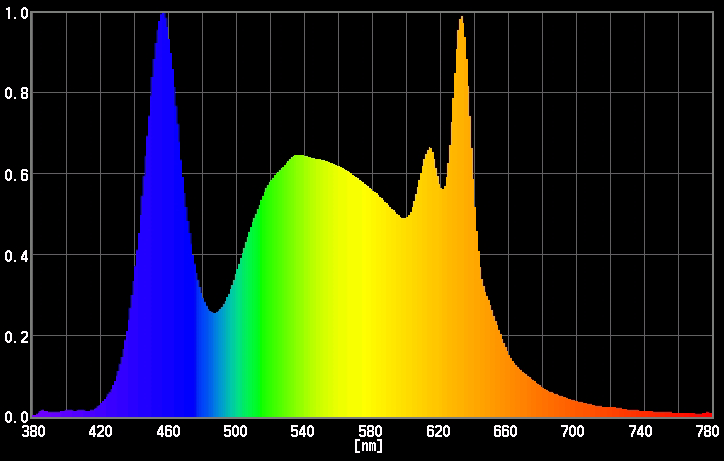

The color rendering of lighting is the focus here. In 2018, GPSE launched sales of the 4-light source full-color LED lighting "Tino4000RA98P" (manufactured by Intexs Corporation, see Fig. 1), which has improved color rendering compared to the typical high color rendering LED light in the market. This product uses a combination of blue, light blue, and green LEDs in addition to typical high-color-rendering LED to simulate natural sunlight (see Fig. 2). As a result, GPSE succeeded in obtaining a flat spectrum close to that of sunlight (see Fig. 3). It is not possible to obtain such a flat spectrum with typical high color rendering LED (see Fig. 4).

Figure 1: Product photo of Tino4000RA98P

Figure 2: Schematic diagram of Tino4000RA98P and typical high color rendering LED. The Tino4000RA98P uses a more advanced structure that combines a high-color-rendering LED with three-color LEDs.

Figure 3: Spectrum of Tino400RA98P

Figure 4: Spectrum of typical high color rendering LED (Ra 93)

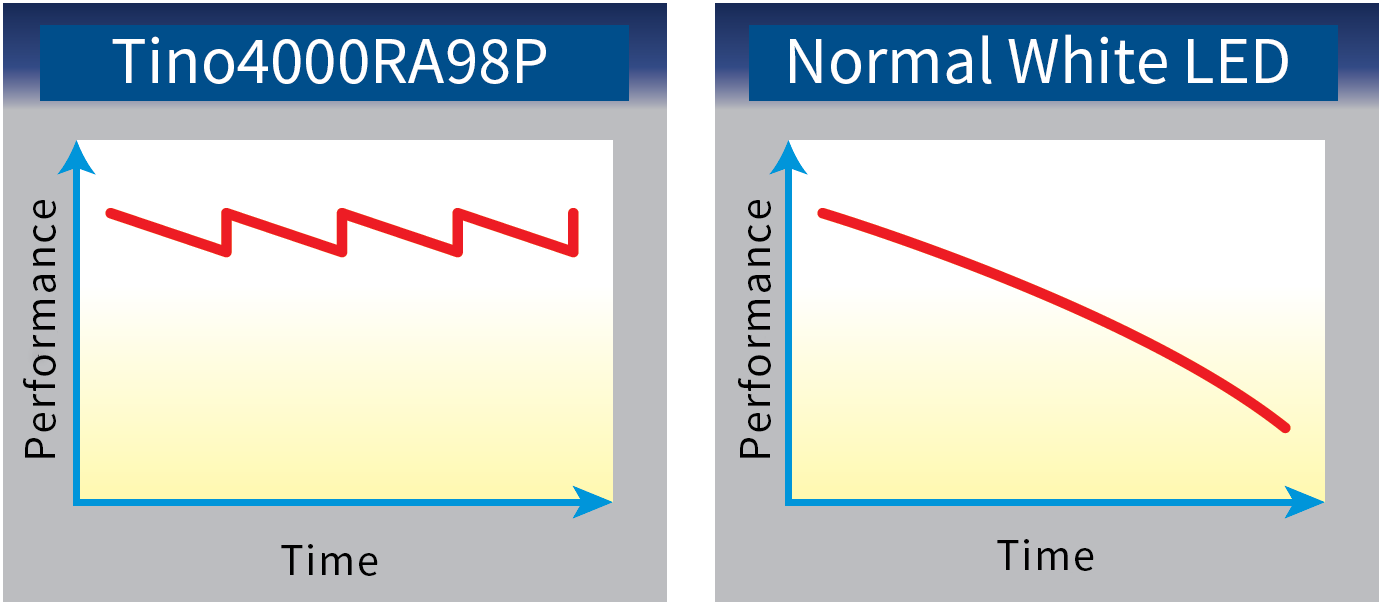

In addition, the Tino4000RA98P is equipped with a color control function that enables color control to achieve a uniform color evaluation environment between different sites and adjustment of spectral distribution disturbance due to deterioration of LED lighting over time. As shown in the schematic diagram on the left side of Fig. 5, the Tino4000RA98P can be adjusted from a state in which performance has slightly deteriorated over time to a normal state. This makes it possible to maintain optimal conditions for a long period of time.

Figure 5: The right is a schematic diagram showing the deterioration over time of a typical white LED. On the left is a schematic diagram showing how the Tino4000RA98P can be adjusted from a degraded state to a normal state.

The environment for color evaluation of printed matter varies depending on the site. Solve on-site problems with digitization by C-7000 and ultra-high color rendering and adjustment functions of Tino4000RA98P.

In the field where color evaluation of printed matter is performed, there are many cases where it is difficult to quantify and visualize lighting environment issues. In such cases, Sekonic's spectrometer C-7000 shows its power. Sekonic's C-7000 is a handheld spectrometer that can quantify and graph the amount, color, and quality of light with a simple push of a measurement button.

■ How to utilize the C-7000: (1) Discover and visualize issues in the color evaluation environment

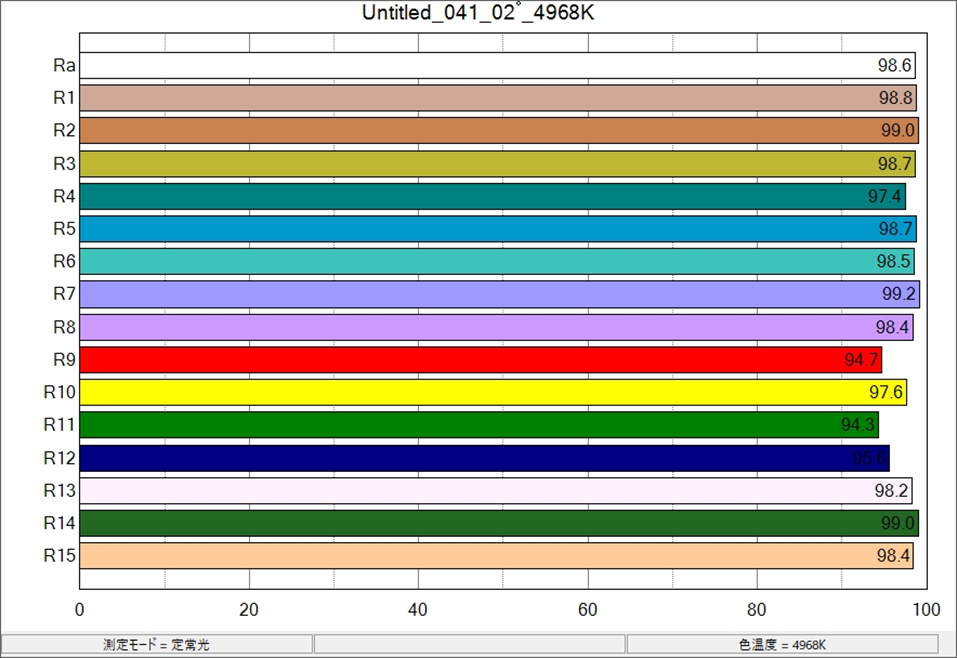

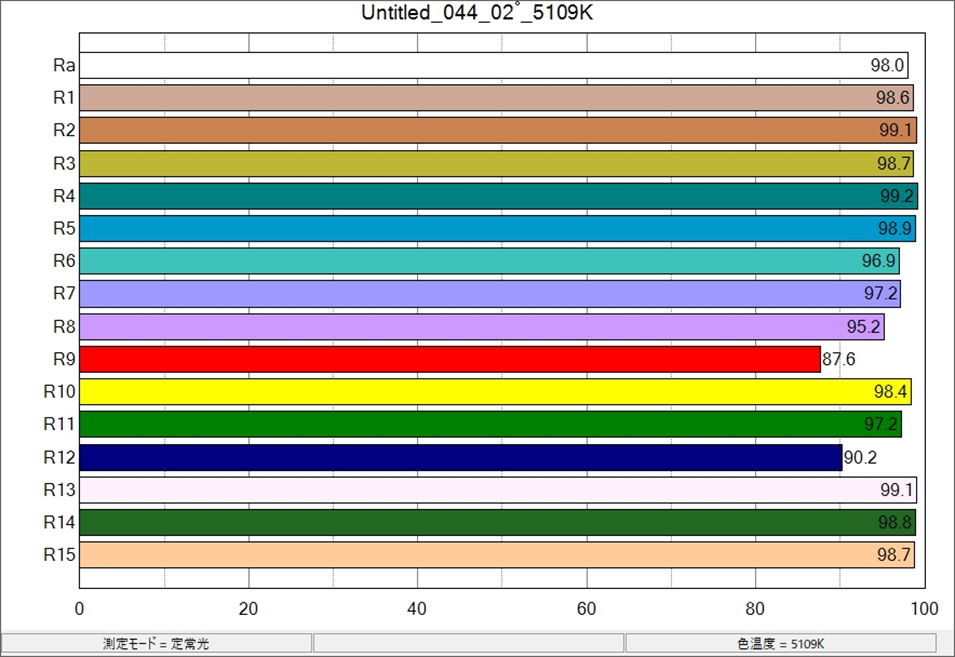

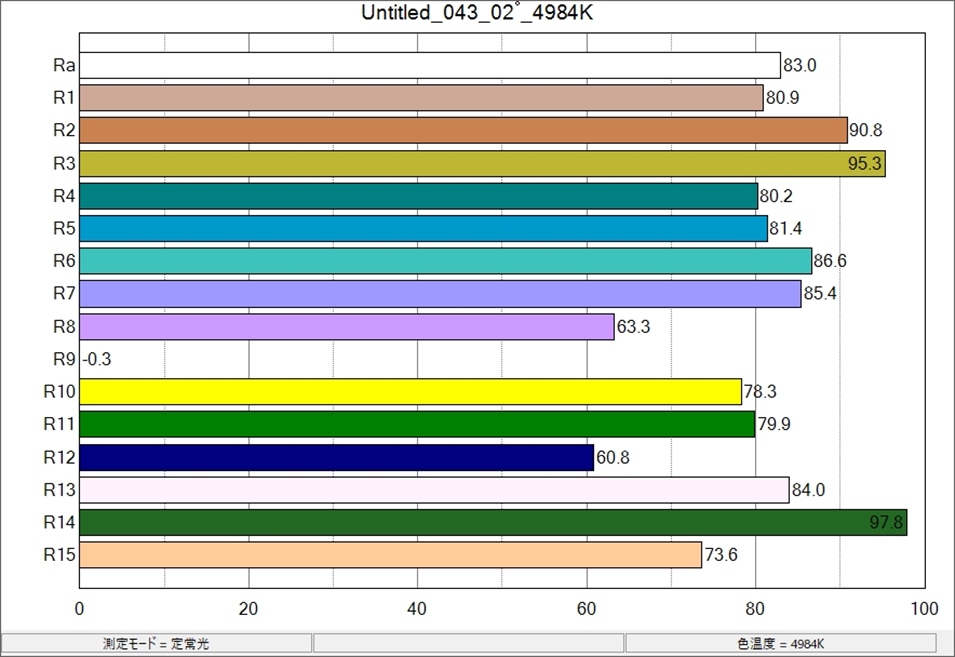

Even if a dedicated high color rendering light is used for the color viewing station, it does not necessarily mean that an ideal environment for color evaluation is achieved. This is because the ceiling lights in the room where the color viewing station is installed often uses general lighting (lighting that does not have high color rendering). In such cases, the light from the ceiling lights affects the lighting environment of the color viewing station, and there are cases where the color rendering is degraded. Fig. 6 shows the C-7000 measurement result of the lighting environment of the color viewing station where the Tino4000RA98P is installed, with the ceiling lights turned off. Ra (General Color Rendering Index) shows an extremely high value of 98.6, and R9 (Special Color Rendering Index for red) also shows a high value of 94.7. However, when we measured the same color viewing station with the ceiling lights turned on, Ra decreased slightly and R9 fell below 90, as shown in Fig. 7. Then, only the ceiling lighting was measured. Ra was as low as 83.0, R9 was a negative value, and R12 was as low as about 60, as shown in Fig. 8. In this way, the C-7000 is an extremely effective tool for identifying problems in the field of color evaluation. And since the Tino4000RA98P can adjust the color rendering performance, it is possible to create an ideal lighting environment based on these measurement data.

Figure 6: Ra=98.6, R9=94.7

Figure 7: Ra=98.0, R9=87.6

Figure 8: Ra=83.0, R9=-0.3, R12=60.8

■ How to utilize the C-7000: (2) Quickly catch aging deterioration through periodical maintenance.

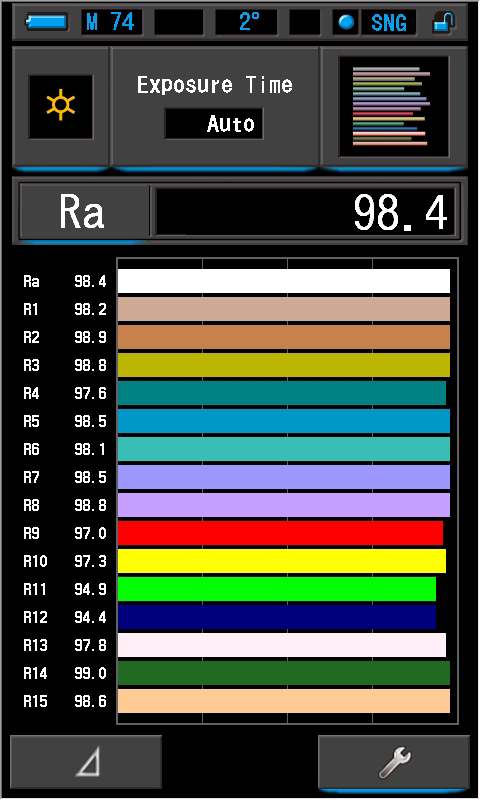

LED lighting is known to have a longer life than fluorescent lighting. However, even though they have a long lifespan, their performance gradually deteriorates over time. The Tino4000RA98P is maintenance-free for 1 to 3 years after installation, but after 3 to 4 years it will need to be adjusted according to the degree of deterioration. Here again, C-7000 can be a great tool. It’s easy to use on-site, and it quantifies and visualizes the amount, color, and quality of light easily. By periodically measuring illuminance (lx), color rendering indexes (Ra, Ri), and chromaticity coordinates (u', v'), it is possible to capture changes in the performance of the Tino4000RA98P based on changes in data over time. This will allow you to take measures early before a problem grows. If you find disturbance in the spectral distribution due to aging, you can use the adjustment function of the Tino4000RA98P to maintain the optimal lighting environment. Fig. 9 shows the state in which color rendering indexes are slightly down due to deterioration over time. As shown in Fig. 10, the Tino4000RA98P allows on-site color rendering adjustment. As a result of the adjustment, the color rendering indexes are restored (Fig. 11).

Figure 9: Ra=96.1, R9=87.9, R12=83.9

Figure 10: Adjustment with remote control

Figure 11: Ra=98.4, R9=97.0, R12=94.4

■ How to utilize the C-7000: (3) Providing standard values for unifying the color evaluation environments of different sites

Color evaluation of printed matter is not only done at the printing factory, but also at various sites, such as meetings with clients at the printing company's office, clients checking samples at their own workplaces and meeting rooms. For example, imagine the case where a printing company's sales representative visits a client's office with a printed sample. This is a sample that has been carefully checked on the color viewing station at the printing company's factory. The lighting for the color viewing station is a Tino4000RA98P, tuned to ideal conditions. It's a perfectly finished sample, so the salesperson is full of confidence. However, the client doesn’t look happy about the sample. The client thinks that the finish of the brand color is different from his image. In such cases, part of the root cause investigation is to check for differences in the lighting environment between the color viewing station in the printing factory and the client's office or conference room. Using the C-7000, the lighting environment at each site can be quantified, and after confirming that the difference in the lighting environment is the root cause, it is necessary to adjust and unify the lighting environment at each site according to the Printed Matter Observation Guidelines (JSPST 1998) of the Japanese Society of Printing Science and Technology. The C-7000 is used to quantify the lighting environment at each site, and the adjustment function of the Tino4000RA98P contributes to unifying the lighting environment at each site.

Responding to the sophistication of color rendering evaluation standards

CRI has been used as an evaluation standard for color rendering of lighting since the days of fluorescent lighting. Even today, when LED lighting is the mainstream, values such as General Color Rendering Index Ra and Special Color Rendering Index R9, which indicates red, are often used as numerical values that indicate color rendering. It is thought that people like the ease of understanding that color rendering is expressed numerically on a 100-point scale, and the intuitiveness of being able to display frequently used colors graphically (see Fig. 12).

Figure 12: C-7000 CRI display mode

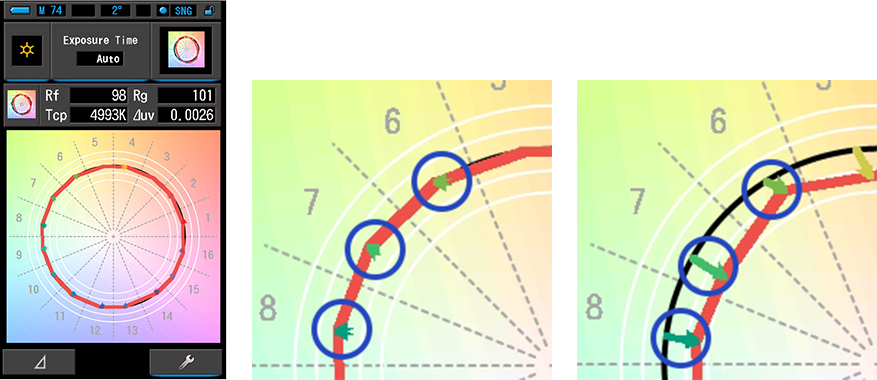

Despite this situation, the Japanese Society of Printing Science and Technology, which formulates evaluation standards for the printing industry, is interested in TM-30, a more advanced color rendering evaluation standard. And GPSE is working towards its dissemination. TM-30 is an international standard stipulated by the Illuminating Engineering Society of North America. Compared to the 15 colors of CRI, TM-30 uses 99 more comprehensive color samples. Therefore, it can be said that it is a more appropriate evaluation standard in the printing industry where various colors are used. The TM-30 has Fidelity index Rf for viewing color fidelity and Gumut index Rg for the vividness (saturation) of the light source. Rf is indicated by a number between 0 and 100, and Rg is indicated by a number between 0 and 200. An Rf of 100 is the same ideal fidelity (color rendering) as the reference illuminant. If Rg is lower than 100, the saturation is low and the color looks dull, while if it is higher than 100, the saturation is high, and the color looks vivid. In this way, TM-30 is a more advanced evaluation standard, but the C-7000 allows you to check the TM-30 values and graphs with the same simple operation as CRI. Fig. 13 below shows the TM-30 display mode screen of the C-7000. Rf value, Rg value and TM-30 graph are shown on one screen. Black circle in the graph indicates the ideal Rg and red circle indicates measured Rg, which might be higher or lower than the ideal Rg. (The measurement result in Fig. 13 has Rg close to 100, so the black circle is almost hidden by the red circle.) If the red circle is inside the black circle, it indicates that Rg is lower than the natural light (desaturated), and if the red circle is outside the black circle, Rg is higher than the natural light (saturated). If the arrow line connecting the black and red circles is off the center of the circle, this indicates hue shift. (The parts circled in blue in Figures 14 and 15 are arrows in the TM-30 graph.)

Figure 13: C-7000 TM-30 display mode.

Figure 14: Enlarged part of Fig. 13. (Arrows circled in blue)

Figure 15: Enlarged part of the measurement result of another light source.

The strongest tag team of Tino4000RA98P and C-7000 to reform the printing industry.

As we have seen above, GPSE is using the C-7000 to expand sales of its flagship product, the Tino4000RA98P, and is promoting the reform of the color evaluation environment in the printing industry. The reasons why GPSE selected the C-7000 as a sales tool can be summarized in the following three points.

1.It is convenient that C-7000 can be carried to the site and measurement can be done immediately.

2.Measurement and display functions can visualize client issues.

3.It has a measurement function for more advanced evaluation criteria such as TM-30.

Since there are more problems to be solved in the field, more activities of the strongest tag team are still expected.

Introducing SCREEN GP's ultra-high color rendering LED lighting and showroom

For more information about the ultra-high color rendering LED lighting Tino4000RA98P, please visit the product page below. (The page is written in Japanese only.)

https://www.screen.co.jp/ga/product/category/color-management-proofing/color-management/tino4000ra98p

Also, at the "Proof Café" in the showroom "White Canvas MON-NAKA", you can experience various solutions related to proofreading. (The interview to write this article was conducted at this cafe.)

Proof Café entrance

Exhibition of actual equipment for various solutions such as color viewing station

For more information on Proof Café and to make a reservation, please see the page below. (The page is written in Japanese only.)

https://www.screen.co.jp/ga/news/info/gpj201225-1

Product information of Sekonic’s spectrometer C-7000

If you are interested in Sekonic's spectrometer C-7000, please visit the product page below. Please feel free to contact us using the inquiry form below for inquiries about our products.

・Spectrometer C-7000

https://www.sekonic.co.jp/english/product/spectrometer/c_7000/c_7000.html・Inquiry form

https://www.sekonic.co.jp/english/support/form_meter.html